2. Glass-fibre reinforced coating

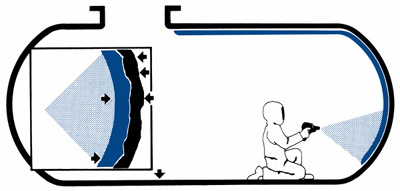

A polyester or epoxy resin lining (possibly glass-fibre reinforced) is applied, under high pressure, to the inner wall of the tank. This coating stops all corrosion from the inside and bridges all perforations due to outer wall corrosion. The thickness and the type of coating depend on the condition of the tank:

- the minimum layer thickness is 0.7 mm (not reinforced) and can go up to a 100% self-supporting tank-in-the-tank

- the coating material used is selected according to the contents of the tank (petrol, heating oil, able to withstand chemicals, suitable for the storage of foodstuffs, …)

- we will be pleased to supply you with the type approvals and official permits for all systems and products that we use

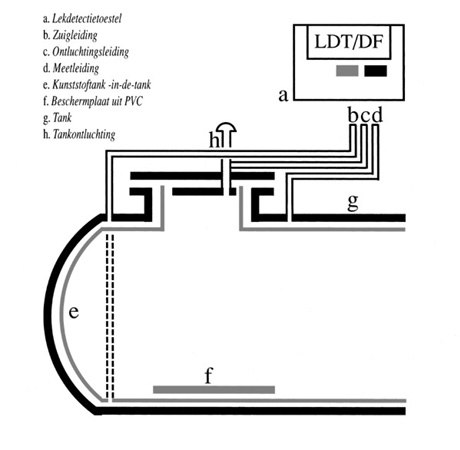

3. Double-wall leak detection

Cibor installs leak detection systems with a double tank wall. This system has the following benefits:

- continuous monitoring of inner- and outer wall

- in case of a leak, the second wall prevents environmental pollution

- The outer wall remains accessible for any repairs

Cibor converts your buried single-walled tanks into double-walled tanks. A made-to-measure inner wall is placed, via the man hole, into the tank and inflated under pressure so that it perfectly assumes the shape of your existing tank. A leak detection device creates a vacuum in the space between the tank wall and the membrane. In case of a leak, the vacuum drops below the preset alarm level, and the leak detection system activates the alarm (acoustic and visual alarm). You know that there is a problem and can take the appropriate measures. The double wall ensures that the product cannot escape.

4. Coating and double-wall conversion of petrol and chemical tanks

For petrol tanks and tanks for the storage of chemicals, CIBOR nv offers the DOPA system in order to equip the tanks with a permanent leak detection system with double barrier. After cleaning and degassing of the tank, this is internally inspected. If serious contamination due to corrosion of the inner- or outer wall is ascertained, a protective glass-fibre reinforced lining can be applied as a mechanical reinforcement. The inner wall is then conditioned, sandblasted and dedusted. A preserving lining is then applied to the steel wall with a special Airless spray device. This 2-component lining has an extremely high resistance to chemicals. After hardening, a special spacer is installed that is used to create a gap. Glass-fibre is laminated to this spacer so that a 2nd artificial inner wall is created in the tank. A vacuum (up to 800 mbar) is created in the gap in order to check the airtightness of the inner- and outer walls. After the airtightness of both walls has been ascertained, a final layer is applied (as a finish) that has an extremely high resistance to chemicals. This layer also guarantees the electrical conductivity in order to enable later safe use of the tank. Naturally, during the assembly, the lining, hardening, conductivity and layer thickness, and the quality during each implementation phase are guaranteed by control measurements on non-porous surfaces. The integrity of the tank is then permanently checked by an Eex-leak detection device that continuously monitors the level of the underpressure in the gap. As this relates to a standing vacuum, this underpressure must remain the same, day in day out, year in year out. False alarms are ruled out. The alarm is only activated if one of the two walls of the tank leaks. However, contamination is not possible provided that one of the two walls remains tight. You have time to take the necessary measures without having to worry about high clean-up costs. This system has also been repeatedly used to re-equip double-walled steel tanks with a permanent leak detection system with double barrier because the outer wall was defective. So the tanks did not have to be dug up. The DOPA system was developed in Switzerland and has already proved its worth for more than 25 years in Switzerland, Germany, the UK, Italy, the Czech Republic, Croatia, Spain, etc. The oldest installation implemented in Belgium dates from 1994. It has already been certified and approved more than 10 times by SGS. The system is also equipped with a prototype approval for Flanders and has already been widely used in Brussels and Wallonia.